SCL OFFERS CONSOLIDATED PORTFOLIO for DIVERSIFIED sectors

FERRO ALLOYS PORTFOLIO

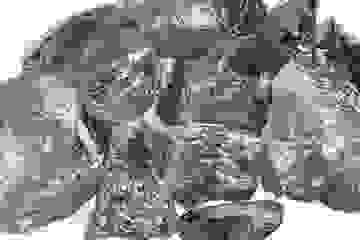

FERRO MANGANESE

FERRO CHROME LOW CARBON

FERRO CHROME

SILICO MANGANESE

FERRO PHOSPHORUS

FERRO MOLYBDENUM

FERRO TITANIUM

FERRO SILICON

INDUCTION FURNACE PORTFOLIO

INSTALLATION OF NEW FURNACE

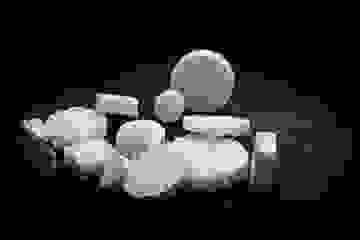

- We offer multiple type of refractories for foundy operations.

- We processed the best raw material at our end so that we can provide High Performance refractories according to your needs.

REFRACTORIES

- ALUMINA BRICKS

- INSULATION BRICKS

- MULLITE BRICKS

- CERAMIC BRICKS

RAMMING MIXES

- DRY RAMMING MIXES

- ACIDIC MIXES

- FIRE CLAY

- CONCRETE CEMENT

- BLANKET

METALLURGICAL PORTFOLIO

BARIUM BASE

- Effective for anti-chilling and for longer fade.

- Clean molten metal can be obtained due to containing few gas (O2,N2).

- More easy to melt down compare with the conventional inoculant .

- Efficiency for improving the form of graphite is almost same as Ca-Si. In case of being used for ductile cast iron,its promotes nodularizing of graphite and brings increase of ferrite.

ZIRCONIUM BASE

- Reduce chill in areas of the casting which cool more rapidly.

- Refine the graphite shape in thin or heavier sections.

- Avoid random coarse graphite flakes, Provide an increase in tensile strength.

- Increase nodule counts, promote good nodule form.

- Modest control of soluble nitrogen in iron.

STRONTIUM BASE

- Highly recommended for gray iron casting as it is thin wall sections castings .

- Increases nucleation rates in gray Iron.

- Neutralizes harmful tramp elements

- Form minimum amounts of slag

METALLURGICAL PORTFOLIO

NODULIZERS CORED WIRE PIPE MOULD POWDER

NODULIZERS

- Basically magnesium treatment of cast iron Makes castings more reliable in as cast conditions.

- Homogeneity and lesser segregation can be achieved if the nodularisers are of very good quality.

- Nodularisers can impart different properties to castings.

- Well-adjusted compositions to your specific foundry needs

- Small addition & simple handling

- Easy & Good traceability

- Availability in Multiple Diameters

- Packing Horizontal & Vertical available

- Different Types of Fillers available

- Designed to reduce surface defects.

- facilitate pipe extraction

- Improves overall casting productivity and costs.

- Control chill in ductile iron pipes and can reduce energy usage during heat treatment.

- Composition/ packaging / sizing can be customized

RESINS PORTFOLIO

SCL - NO BAKE SYSTEM

- Furan & furan phenolic no bake resins with a low content of nitrogen or nitrogen free.

- Furanand phenol furan resins with less than 0.5 % nitrogen, not classified as toxic according to the current European classification of furfuryl alochol.

- Phenolic No Bake Resins.

- Alkaline Phenolic No Bake Resins

- Phenolic Urethane & polyol urethane no bake resins with or without aromatic solvents and VOC.

- Inorganic binder Systems

- Nobake system basked on alkyd resins.

SCL-URETHANE GAS CURED SYSTEM

- Phenolic Urethane Cold Box Resins with vaporized tertiary amine.

- Phenolic urethane cold box resins , free from aromatic solvents and VIC , catalyzed with vaporized tertiary amine.

- Alkaline -phenolic resins catalyzed with vaporized esters.

- Sulphur dioxide Catalyzed epoxy arcylic resins.

- Inorganic binders for curing with carbon dioxide.

SCL HOT CURED SYSTEM

- Furan , phenolic & furan phenolic for the hot box processes.

- Furan resins for the warm box process.

- Furan & phenolic resins for the thermoshock processes.

- Liquid phenolic resins for shell moulding precoated sands.

COATINGS PORTFOLIO

WATER BASED GRAPHITE OR ZIRCONIUM SILICATE COATINGS

- Suitable for all alloy offering maximum refractory characteristic , excellent for Steel

- Good refractory performance, excellent spray properties.

- Offers excellent surface finish for most Ferrous & Non Ferrous Application.

- General all purpose coating for Iron Foundries for lighter section & Weight castings.

- Heavy Iron , excellent brush & Flow Properties.

ALCOHOL BASED GRAPHITE OR ZIRCONIUM SILICATE COATINGS

- Versatile Coating for most alloys including non ferrous , good brush and spray properties.

- Effective Anti Veining , excellent brush coating.

- For Iron & Steel Alloys particularly good where lustrous Carbon in concern.

ALCOHOL BASED THINNERS OR ALCOHOL BASED COATINGS

- Assists chilling of cast areas, used with Grey, Ductile Iron & Non Ferrous Alloys.

- Versatile for Simple casting and good for flow casting.

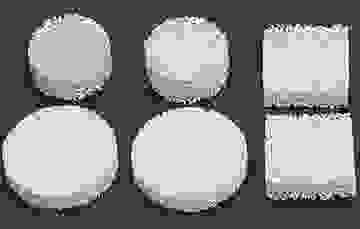

FILTRATION PORTFOLIO

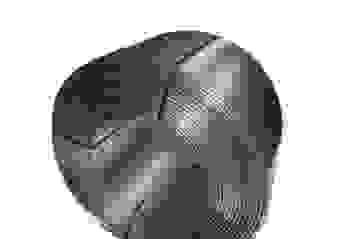

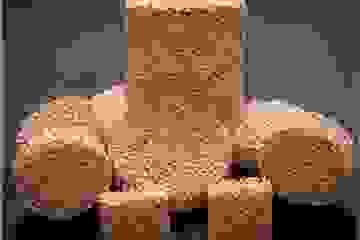

CERAMIC FOAM FILTER

- Three dimensional connected porous channel.

- Remove large non metallic inclusions.

- Deep adherence & reduce turbulence.

- Effective enhance qualification rate.

- Improve metallurgical structure of metal products.

SILICON CARBIDE CERAMIC FOAM FILTER (CFS)

- Apply to improve the quality of ductile, grey and malleable iron casting.

- Help to slow the turbulence of the pouring gate.

- With excellent thermal shock resistance and high temperature strength, it can withstand the extreme environment in the process of iron casting.

- Purify molten iron & Improve the quality of iron casting.

- Reduce inclusion of iron casting .

- Stabilize mould filling time

HONEY COMB CERAMIC FOAM FILTER

- Large Surface area & good thermal stability.

- High Porosity & stable chemical performance.

- Low resistance property & high temperature resistance.

- Energy usage efficiency increases by 50 %.

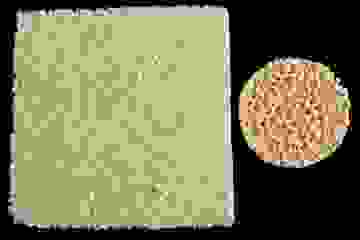

ALUMINA CERAMIC FOAM FILTER (CFA)

- Apply to improve the quality of aluminum alloy and other non-ferrous alloy casting.

- Improve metallurgical structure.

- Enhance mechanical properties .

- Change turbulence into laminar flow.

ZIRCONIA CERAMIC FOAM FILTER (CFZ)

- Purify molten steel.

- Enhance the yield of steel casting.

- Reduce inclusion of steel casting.

- Decrease internal re-oxidation defects.

- Reduce the sub-surface defects after machining.

MAGNESIA CERAMIC FOAM FILTER (CFM)

- As the magnesium alloy is more active than any other non-ferrous metals, the high-temperature molten magnesium alloy can easily react with the main-material of ceramic foam filter.

- Filter is just used for purifying molten magnesium alloy and filling the gap of domestic market.

- Purify molten magnesium alloy .

- Improve the inner quality of magnesium alloy

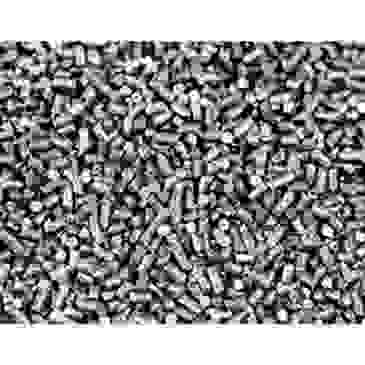

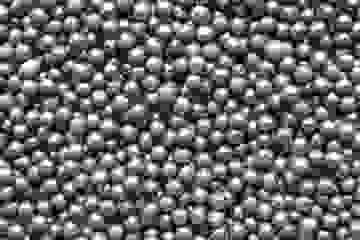

STEEL SHOTS/STEEL GRITS- SURFACE FINISH PORTFOLIO

SCL is supplying abrasive blasting materials since 1987.SCL have venture with their Partners who have TQM for producing the Global standard quality for shot blasting,shot peening, stone cutting, and also along with other advanced Multiple range of products.

HIGH CARBON STEEL ABRASIVES

- Due to the use of High Quality scrap/ while manufacturing the shots. Our abrasives have very less dust generation with which assure the customers for the improvement in the life of spares.

- Our Abrasives follow consistent Quenching Process.

- SAE/ISO standards are followed

- Our Abrasives have Eroding Behavior

- The increased cleaning efficiency of High Carbon Steel Shot will give:-

Improved Quality

Increased Productivity

Reduced Costs

LOW CARBON ABRASIVES

- lower consumption of blast media

- lower machine wear

- better surface coverage

- less dust

- SAE Standards are followed

STAINLESS STEEL ABRASIVES

- It protects the material from being discolored & provides the bright cleaned surface.

- Blasting with this will help to achieve better surface treatment on materials, as it will protect from corrosion and black spots.

- As a result, it provides high performance, which will satisfy the needs of the customers

wwww.sclgrouponline.com

SCL Cut Wire Steel Shots

Cut Wire Steel Shots

Stainless Steel Cut Wire Steel Shots

Copper Cut Wire Steel Shots

SCL Cut Wire High quality Shot boosts the performance of your parts in a cost-efficient and sustainable way. Produced by cutting steel wire into lengths equal to the wire diameter, cut wir is a mono grain size abrasives with a good service life at high blasting velocity. Number of peening applications require cut wire steel shot to deliver the impact energy into the metal surface.

Copper Cut Wire Steel Shots

Stainless Steel Cut Wire Steel Shots

Copper Cut Wire Steel Shots

SCL offered Copper cut wire shots as desired by the end users requirement & specifications. CCWS that are manufactured by cutting wire into lengths equal to wire diameter. These copper cut wire shots are find application in various industries for shot blasting, shot peening .

Stainless Steel Cut Wire Steel Shots

Stainless Steel Cut Wire Steel Shots

Stainless Steel Cut Wire Steel Shots

SCL Stainless steel cut wire shot are made from type AISI 316/304/202/430 Stainless steel wire having uniform hardness of 400 to 500 VPN or as per the requirement desired by our user end . It give you extra wide finish, and dust accumulation will be zero. Life will be approx 9-10 times higher life than Steel Shots/Grits AND 5-6 times

SCL Stainless steel cut wire shot are made from type AISI 316/304/202/430 Stainless steel wire having uniform hardness of 400 to 500 VPN or as per the requirement desired by our user end . It give you extra wide finish, and dust accumulation will be zero. Life will be approx 9-10 times higher life than Steel Shots/Grits AND 5-6 times higher life than Steel Cut Wire Shots.

Our Stainless Steel Cut wire shots is being used in important applications where ferrous contamination in blasting stainless steel, aluminium, or other non ferrous work objects could be harmful.

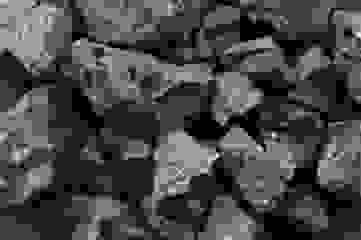

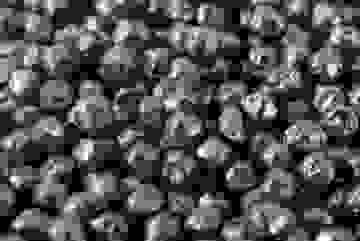

Chromite Sand

Grade Size AFS 45-55

. Chromite sand ,Primarily for use as either a molding sand or as a core sand in the production of steel castings. SCL Foundry grade chromite sand is derived from naturally occurring chrome ore . The grains are irregularly shaped, angular and commonly with somewhat curved faces. The color is jet black with a metallic luster.

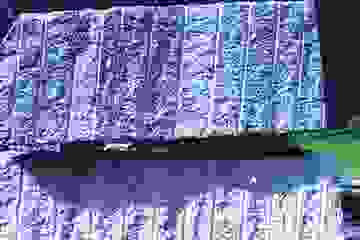

Trigno-S SteelGrits More than 60 + HRC Cutting/SAWING Proces

Trigno - S Steel Grit for Stone Cutting Gang-Saws to process granite blocks.

Trigno- S Steel Grit are applying vital role due to close monitoing for tolerances on size and hardness which is more than 60 HRC for smooth cutting speeds and allow for long cutting life under lower costs .

Trigno-S Steel Grits is very much renowned for smooth sawing/cutting of the Granite Slice

During the cutting of Slice of granite under the lower consumption of Trigno - S .i.e. Steel grits.

Trigno-S is very much popular for excellent surface finish of Granite Slice during the sawing process through Gangsaw .

Trigno -S more than 60+HRC

Steel Grits

Benefits of uses

Lower Consumption

Low maintenance of machine during sawing.

Excellent for the surface finish of Granite slice.

High speed cutting with lower consumption of Trigno-S .

Additive Bentonite Portfolio

Bentonite G -SCL

Bentonite GIB-SCL

Bentonite GIB-SCL

Bentonite SCL Resources is a leading supplier in Asia and others markets several bentonite products.This hugely versatile clay is used in a wide range of industries as such applications including high performance of binding, Foundry, Borewell,Oil & Gas Drilling and Water purification also.

Bentonite GIB-SCL

Bentonite GIB-SCL

Bentonite GIB-SCL

Bentonite for use in foundry green sand molding and other alloy castings.

- High purity material, less sand content as fine powder.

- Better shake out property, low consumption.

- Engineered GCS and WTS ensure, initial low SCL Bentonite for use in foundry green sand molding and consumption and very less rejection.

Bentonite GI-SCL

Bentonite GIB-SCL

Bentonite GI-SCL

Bentonite for suitable for critical castings. The quality of bentonite bonded molding sand is determined by its molding, casting and reclamation behavior. Molding sand additives from SCL offer high and consistent quality combined with long term availability through regular effective resources.

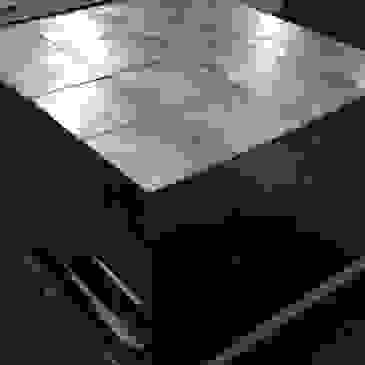

solution provider for steel industry Globally

MAGNESIA CARBON BRICKS

MAGNESIA CARBON BRICKS

MAGNESIA CARBON BRICKS

- SCL have a force to drive the refractories products for their Partners .

- As global refractory supplier, we are in a position to drive positive change in our steel industry.

- We offer a complete product and service portfolio for all steel industry processes.

- Ranging from reduction up to their finish products through their rolling mills.i.e.

- SCL have a force to drive the refractories products for their Partners .

- As global refractory supplier, we are in a position to drive positive change in our steel industry.

- We offer a complete product and service portfolio for all steel industry processes.

- Ranging from reduction up to their finish products through their rolling mills.i.e. reheating furnaces, through steel making and ingot casting.

- The integration of core competencies, setting common objectives and working jointly at the customer’s shopfloor .

- With basic and non-basic bricks and mixes, slide gate plates, isostatic products and prefab components to special machinery, mechanisms and repair systems, our products and customized services and solutions are the key to a unique delivery to our customers end..

- Product quality combined with high value technical experience makes us stronger together. SCL is ready for your challenge.

GRAPHITE ELECRODES

MAGNESIA CARBON BRICKS

MAGNESIA CARBON BRICKS

SCL is supplying 4 Types of Electrodes i.e. UHP Graphite electrodes, SHP Graphite electrodes, HP Graphite electrodes, RP Graphite electrodes.

They are mainly used in electric arc furnace.

They are presently the only products available that have the high levels of electrical conductivity and the capability of sustaining the extremely hi

SCL is supplying 4 Types of Electrodes i.e. UHP Graphite electrodes, SHP Graphite electrodes, HP Graphite electrodes, RP Graphite electrodes.

They are mainly used in electric arc furnace.

They are presently the only products available that have the high levels of electrical conductivity and the capability of sustaining the extremely high levels of heat generated in EAF.

Graphite electrodes are also used to refine steel in ladle furnaces and in other smelting processes.

Size & Grade Selection be particular

To properly select the right SCL Graphite electrode for your application, always consider the following operating characteristics of your furnace which is manufactured by our Partners.

Conversion Cost

- Steel type and grade

- Electrode consumption

- Refractory consumption

- Productivity

- Electrode strength and oxidation

Furnace design

- Scrap types/charging practice

- Burner/oxygen usage

- Water spray rings

- Fume control system

Power Input Program

- Meltdown/refine/tap-to-tap time

- Power level

- Slag practice

DOLOMITE BRICKS

MAGNESIA CARBON BRICKS

DOLOMITE BRICKS

- SCL Dolomite refractories are made of magnesium oxide, about 30%-42%, calcium oxide, about 40%-60%, and other materials, and the main minerals are Pericles and the calcium stone at their Partners end .

- Such products are featured with high refractoriness, good thermodynamic stability, and slag erosion resistance. And can be used in the con

- SCL Dolomite refractories are made of magnesium oxide, about 30%-42%, calcium oxide, about 40%-60%, and other materials, and the main minerals are Pericles and the calcium stone at their Partners end .

- Such products are featured with high refractoriness, good thermodynamic stability, and slag erosion resistance. And can be used in the converter, steel making furnace and sintering zone as well as transition zone of the cement rotary kiln, etc.

Slide Gate Refractories

Slide Gates & Slide Gate Refractories

- Reduce ladle turn-around time.

- Enable more efficient ladle management.

- Reduce overall ladle refractory, labour and energy costs.

Shrouds ,Nozzles & Stoppers

- ISO-statically pressed carbon bonded alumina-graphite stopper-rods and nozzles.

- Clay composition extruded sleeves.

- Steel rods/rigging and mortars are also available.

- Hydraulically pressed clay nozzles and clay-graphite stopper-heads.

- One piece stoppers are typically a single composition, but can feature some of the same design and multi-composition as those used for continuous casting. Ensures free opening of nozzle.

- - Minimizes oxygen lancing and reduces cost.

- - Increases the life of slide gates and nozzles.

Copper Mold Tubes

- We customize copper mold tubes according to your specific needs.

- Our Experts also help you to determine the best composition length and taper to maximize the performance of your caster and to optimize your quality.

Megnesia Bricks Lining for LRF

Megnesia Carbon Bricks-LRF

Megnesia Carbon Bricks-LRF

Megnesia Carbon Bricks-LRF

SCL MAGNESIA CARBON REFRACTORIES FOR LRF WORKING LINING

SCL ALU MAGNESIA CARBON BRICKS FOR METAL ZONE, IMPACT PAD & BOTTOM

SCL HA & CHROME MAG SAFETY BRICKS

SCL HA LOW CEMENT CASTABLES

PRECAST SHAPES OF LADLE BOTTOM AND WELL BLOCKS

Delta Bricks

Megnesia Carbon Bricks-LRF

Delta Bricks

.

SCL ROOF DELTA BRICKS AND CASTABLES

SCL PRE-CAST ROOF DELTA

SCL EBT FILLING MASS